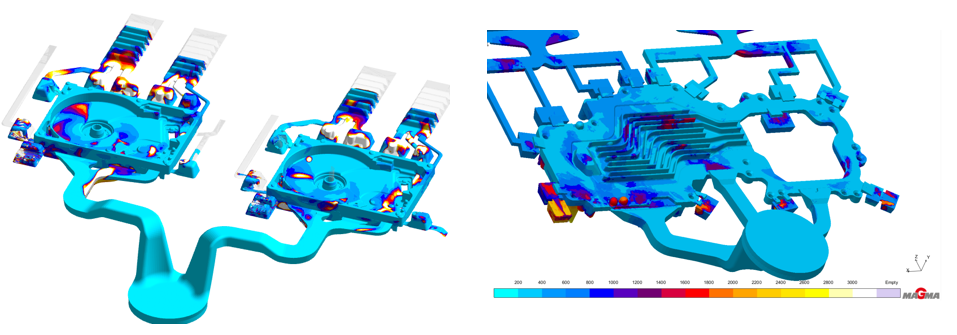

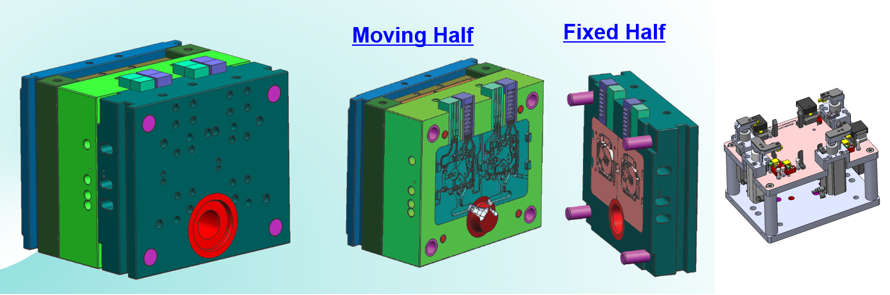

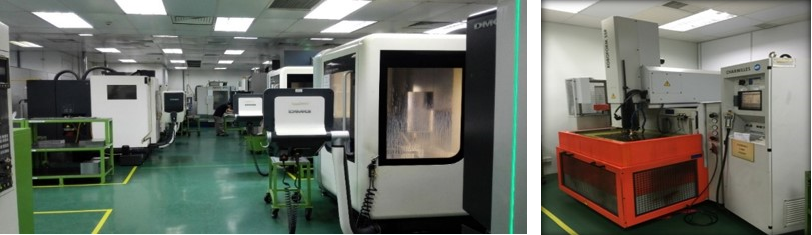

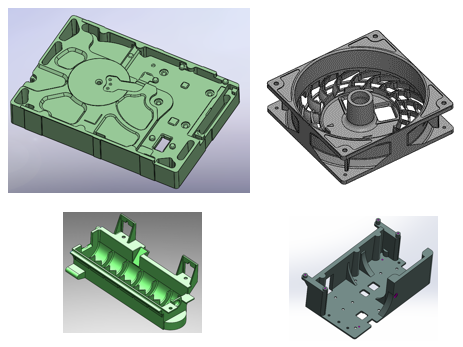

We specialized in the aluminium die casting mold and process development. We offer our customer a wide range of services from product design optimization (DFM), mold flow analysis (CAE), mold design and fabrication, as well as support in die casting process, failure analysis and quality improvement.

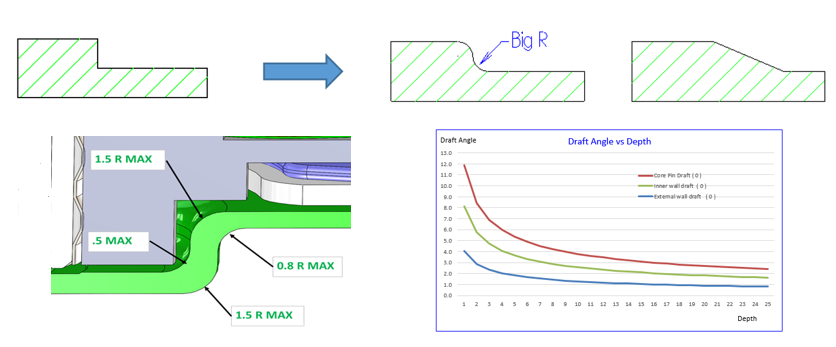

To optimize the product design for quality improvement: